our equipement capabilities

MILLING

FADAL 4020A_40 X 20 X 15

The Fadal 4020A offers a 40 x 20 x 15-inch work area, ideal for precise and complex machining tasks. Known for its reliability and accuracy, this machine is perfect for producing high-quality parts in various industries.

FADAL VMC40_22 X 16 X 15

Our Fadal VMC40 Vertical Machining Center features a robust 22″ x 16″ x 15″ travel capacity, ideal for precision machining tasks. With spindle speeds up to 15,000 RPM and a 21-tool automatic changer, it ensures efficient operations and high-quality results across various materials, from metals to plastics.

FADAL 3016_30 X 16 X 15

The Fadal 3016 Vertical Machining Center offers a compact yet robust solution with a travel capacity of 30″ x 16″ x 15″. Ideal for precise machining tasks, it features a high-speed spindle and a 21-tool capacity automatic tool changer, ensuring efficient operations across a range of materials.

MORI SEIKI NH4000

The Mori Seiki NH4000 is a high-precision horizontal machining center designed for efficient and accurate production. Known for its robust construction and advanced technology, it excels in creating complex and tight-tolerance parts for various industries.

MORI SEIKI N5000

The Mori Seiki NH5000 is a high-precision horizontal machining center featuring a 19.7″ x 19.7″ pallet size, 24.8″ X-axis travel, 23.6″ Y-axis travel, and 26.4″ Z-axis travel. Equipped with a high-speed 14,000 RPM spindle, 60-tool automatic tool changer, and a full 4th axis rotary table, it excels in producing complex, tight-tolerance parts with efficiency. Additional features include rigid tapping, coolant through spindle, and advanced FANUC 18iM CNC control for superior performance in demanding applications.

HAAS VF-6

The Haas VF-6 Vertical Machining Center is a versatile solution for precision machining tasks. With a spacious work envelope and robust construction, it offers a generous 64″ x 32″ x 30″ travel capacity. Equipped with a powerful spindle capable of speeds up to 8,100 RPM and an automatic tool changer with 24-tool capacity, the VF-6 ensures efficient production and consistent performance across a wide range of materials.

LATHE

FEMCO HL-25

The Femco HL-25 CNC Lathe is a versatile machine designed for precision turning operations. It features a robust construction and offers a maximum turning diameter of 20 inches and a maximum turning length of 40 inches. Equipped with a powerful spindle and a turret with multiple tool stations, the HL-25 ensures high efficiency and accuracy in machining various materials.

MORI SEIKI SL-253M

The Mori Seiki SL-253M CNC Lathe is renowned for its precision and versatility in turning operations. Featuring a maximum turning diameter of 20 inches and a maximum turning length of 22 inches, it excels in handling complex machining tasks with ease. Equipped with a high-performance spindle and a turret with multiple tool positions, the SL-253M delivers exceptional accuracy and efficiency for a wide range of materials.

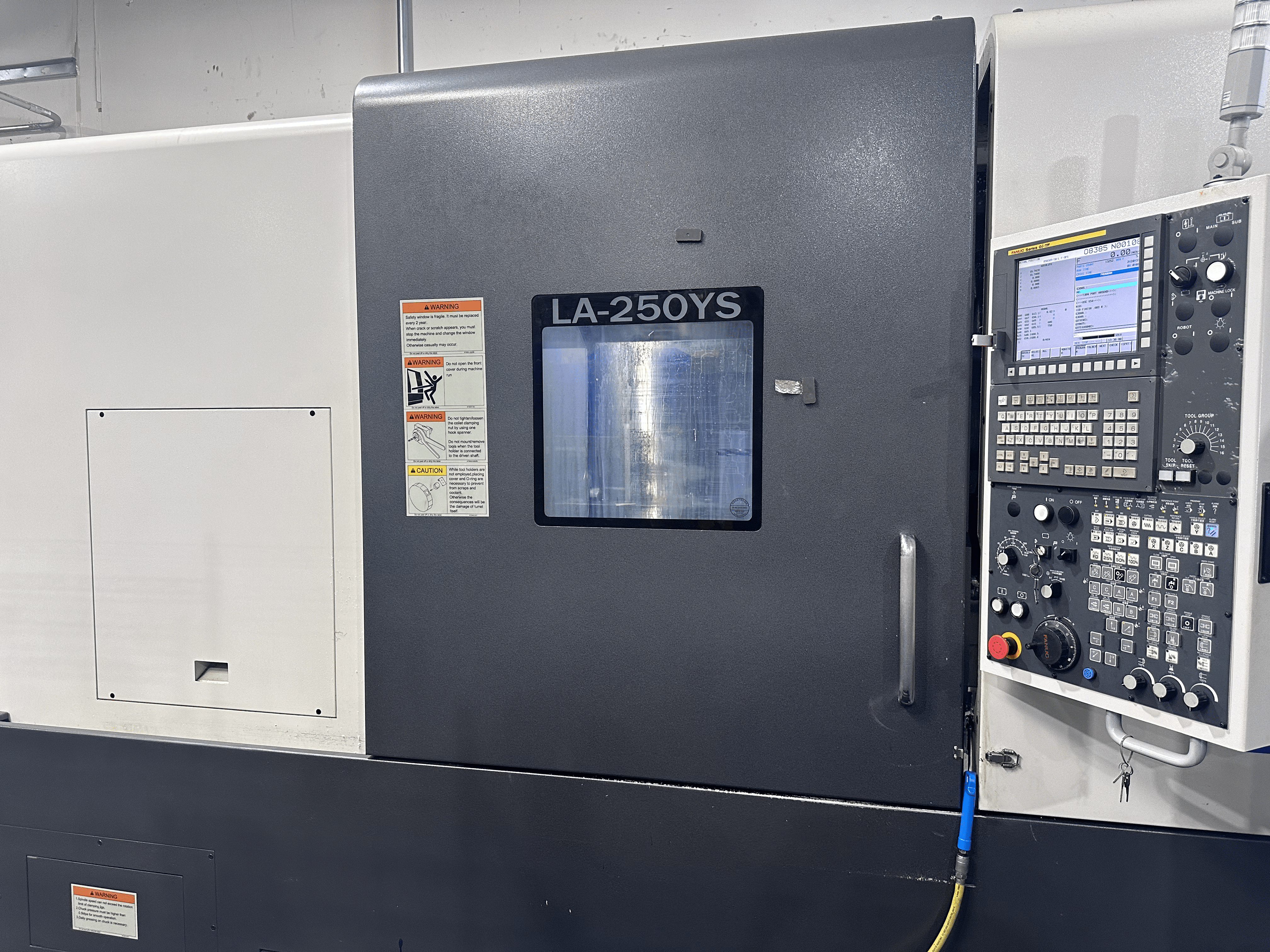

TAKISAWA LA-250YS

The Takisawa LA-250YS CNC Lathe is a highly capable machine designed for precision turning and milling operations. It features a maximum turning diameter of 280 mm (11 inches) and a maximum turning length of 530 mm (20.9 inches). Equipped with a powerful spindle and Y-axis milling capability, it offers versatility for complex machining tasks.

TAKISAWA LA-250M

The Takisawa LA-250M CNC Lathe is optimized for precision turning operations. With a maximum turning diameter of 350 mm and a turning length of 500 mm, it features a powerful spindle and live tooling capability. This allows for efficient machining of various materials, making it a versatile choice for manufacturing needs.

MORI SEIKI SL-253

The Mori Seiki SL-253 CNC Lathe is ideal for precision turning operations. With a maximum turning diameter of 20 inches and a turning length of 22 inches, it features a high-performance spindle and a turret with multiple tool positions, ensuring reliable and accurate machining across a wide range of materials.

SINKER EDM

Available for service through our facilities, excels in precision machining by using electrical discharges to shape metal. This process is ideal for creating complex shapes and features in hardened materials that are difficult to machine with traditional methods.

GLOBAL S CMM

A precision measurement tool owned and serviced by us, capable of accurate dimensional inspection across a wide range of parts and materials. With advanced probing technology and a robust granite base, it ensures reliable quality control and verification in manufacturing processes.

AMADA AUTOMATIC SAW

The Amada automatic saw, part of our equipment and service offerings, is designed for precision cutting tasks. With automated operation and advanced cutting capabilities, it ensures efficient and accurate cutting of various materials, making it ideal for industrial applications.